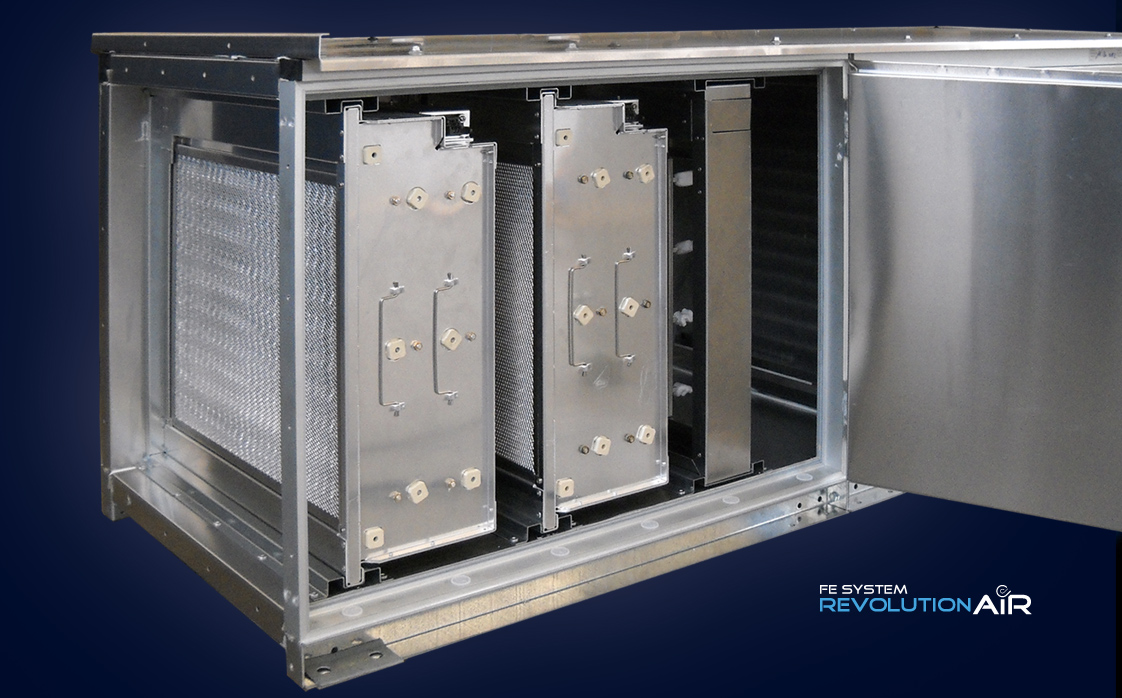

Recommended for Small Restaurant and Residential Kitchens

OzoneCo offers the new range of exhaust filtration units for kitchens with compact size, especially suitable for installation in small kitchens in historic centers: ECOLIGHT.

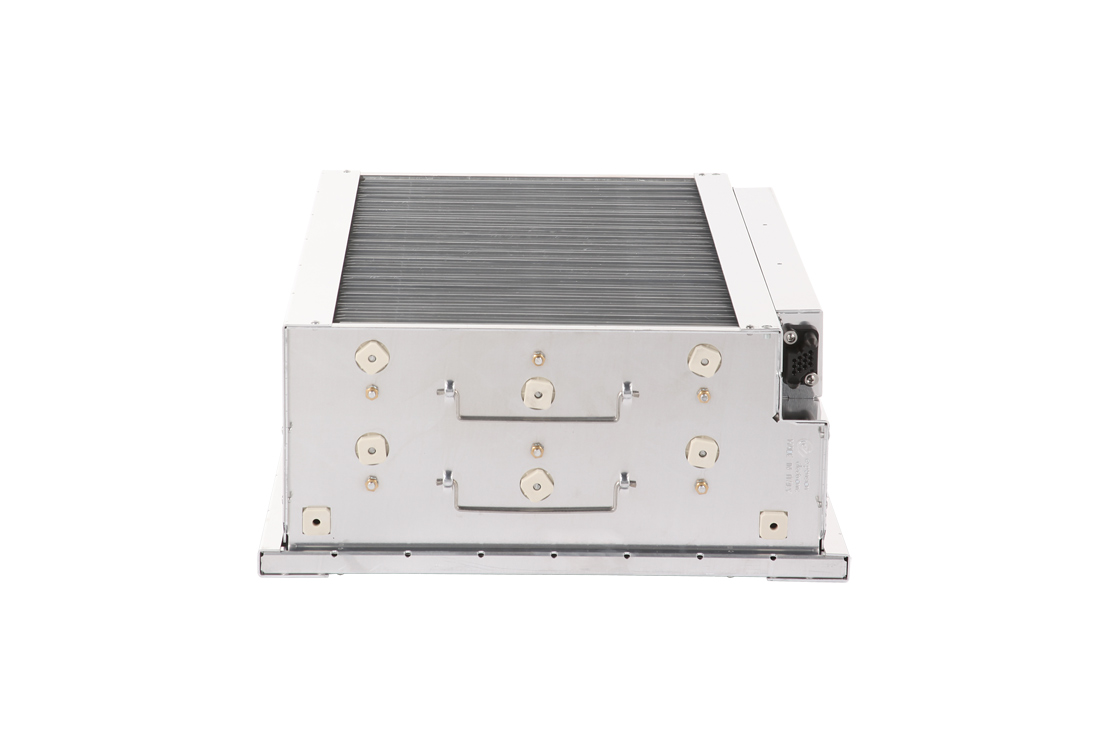

The FEL System filter installed as standard has been specifically designed for the removal of pollutants such as oil mist and vapors thanks to pointed collection blades that allow the capture and drop down high quantities of oily pollutant downwards.

Ecology

Energy Saving is guaranteed as energy consumption is 3 times lower than that of a mechanical filter with equal filtration efficiency: this is mainly due to the low pressure drops almost constant over time, 62 Pa even when the filter is completely dirty. The low energy consumption of the ECOLIGHT units is also guaranteed by the use of an electronic motor instead of a belt motor. They are equipped with a new 3-stage prefiltration completely removable and washable. The possibility of installing before the activated carbon the combination of an ionization cell FI and an ozonation cell FX provides a hygienic and antibacterial effect and at the same time reduces odors.

ECOLIGHT FEATURES

The installer will not have to provide any drainage system since the units are equipped with a removable tray designed tray to collect the oil captured by the electronic filter.

RETROFIT FOR THE COMFORT AND ENERGETIC PERFORMANCE IMPROVEMENT

Plants characteristics with Electrostatic precipitators (electrostatic filters):

These are the basic features, to which is added an extremely important plus: an efficient antifungal and antibacterial action, in order to avoid the proliferation of bacteria colonies and molds in certain favourable conditions of temperature and humidity, often encountered in typical treatment plants air. For these reasons, and in order to reduce environmental impact, Expansion Electronic has implemented a retrofit’s action that allows you to replace the normal mechanical filters with those of new electrostatic generation one.

The advantages are mainly two:

MECHANICAL FILTER WITH ELECTROSTATIC CHARGE

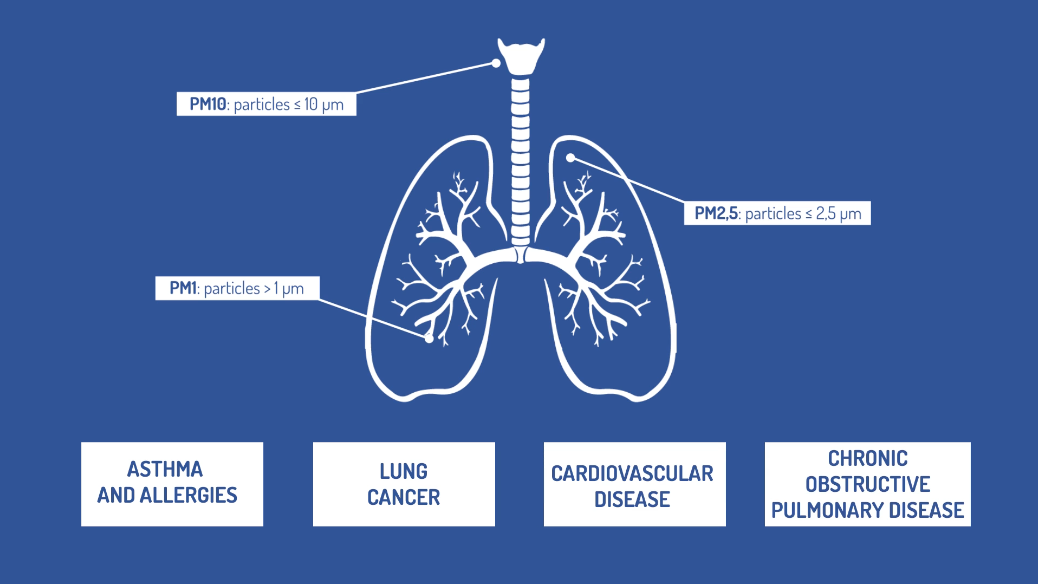

In the electrostatic filtering systems technology there is an electrostatic effect when a polluting particle (dust, smoke, fibers, etc ...) has, on its surface an electric charges (positive and/or negative) that makes it adhere to another surface (filter’s fiber, walls, curtains, TV and laptop screens, etc..) with equal but opposite charge. If the particle mass is sufficiently small, the electric charge presents on its surface makes it adhere to another opposite electric charge, present on the surface of the mattress filter.

When this phenomenon is enhanced artificially, electrostatically charging the fibers of a filter you will obtained a “passive electrostatic filter”, which in order to work well must be made with very high electrical resistivity fibers, as for example the rectangular plastic fibers. Its negative aspect is that just the deposit of polluting particles on the filter fibers makes it immediately decrease the ability of pollution’s abatement.

Moreover, if the environment is particularly damp, the water contained in the air condenses on the surface of the fibers and eliminates them in a very short time each electric charge, transforming the product into a simple mechanical sieve filter. To overcome this problem the so-called ‘buffer’ filtering systems were created, in which the filtering means are submerged in an electric field which maintains the attraction power and the pollutants retention. The negative side is in the operation, starting from the fact that it depends on a filter mattress (the so-called buffer) that, even if electrostatically charged, presents the same disadvantages of the mechanical filters.