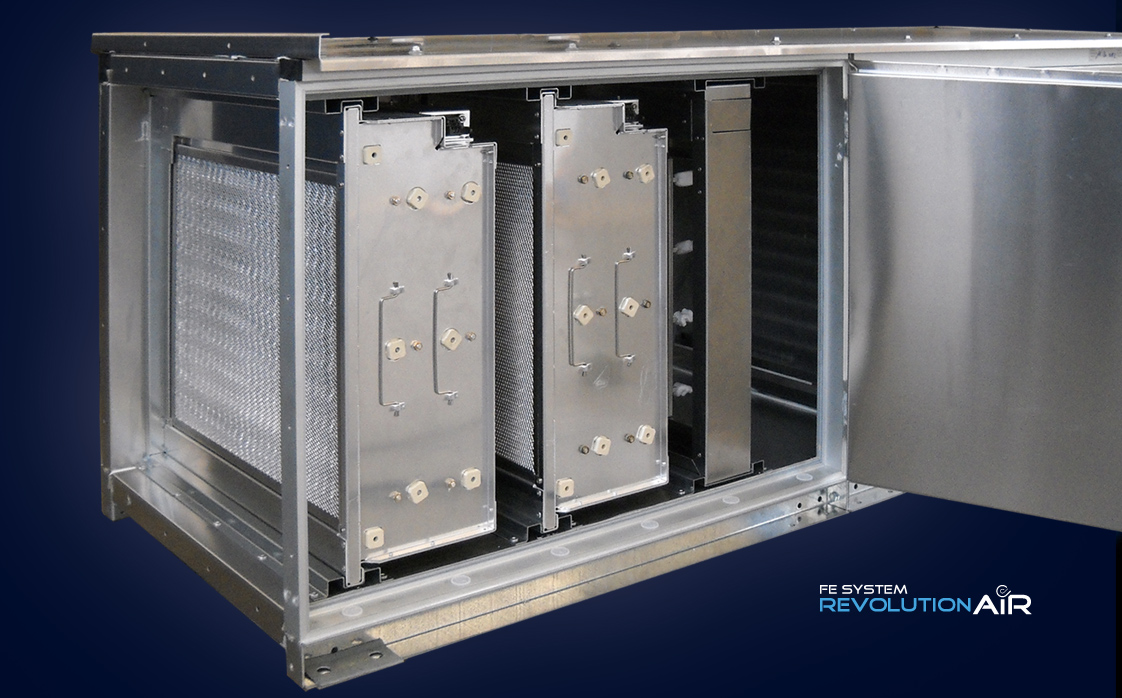

The new range of electronic air filters FE SYSTEM, could be installed in: - air handling units (electrostatic filter for AHU); - rooftop (electrostatic filter for Rooftop); - ventilation ducts.

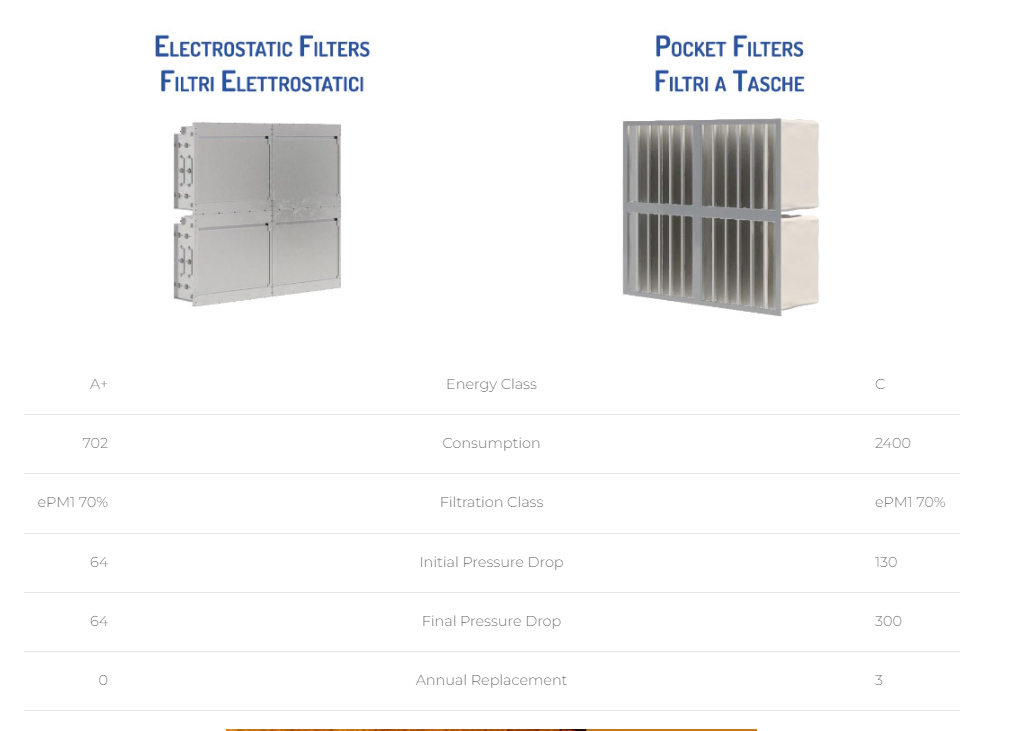

As atmospheric pollution worsens, particularly in industrialized nations, the demand for air filtration is skyrocketing. In line with sustainable development goals, reducing the power consumption of filtration systems has become paramount and is the subject of extensive research. The new FE SYSTEM series of active electrostatic filters with integrated electronics has been specifically designed to address this need.

Electrostatic filter FE SYSTEM offers a viable alternative to traditional pocket filters and was engineered to simplify the incorporation of electrostatic filters into AHUs and rooftops. Its use in ventilation systems, especially in the air-conditioning industry, does not necessitate any modifications to the plant's construction or dimensions.

ENERGETIC EFFICIENCY

Energy efficiency in ventilation systems has become a topic of intense debate and interest in recent years. The air handling process, which involves treating air through a treatment unit, consumes a significant amount of energy.

The amount of energy wasted depends on the pressure drop, which is directly proportional to the filter's efficiency class (and therefore its level of obstruction) and the desired indoor air quality.

Any "mechanical" air filter, whose efficiency is primarily determined by mechanical interference phenomena between the airborne particles and the filtering fibrous matrix, experiences a progressive increase in load losses as deposits accumulate perpendicular to the airflow. For instance, a medium-to-high-efficiency paper filter, classified as F7-F8 according to EN 779, may have an initial pressure drop of 100-150 Pa, which can increase to up to 450 Pa at the end of its lifespan.

MECHANICAL FILTER

The mechanical filters are constituted by “little mattress” of mineral fibers, obtain by plants or artificially, through which passed the air. Classified according to their greater or smaller ability to hold particles, the more efficient are defined HEPA (High Efficiency Particulates Air Filter), able of blocking into their tangle mites faeces, pollens, bacteria and any higher particles higher on diameters than their minimum filter length, which on average is from 0.3 to 0.9 microns (the size of a pollen can go from 5 to 250 microns, while that of a virus can vary between 10 nm and 700 nm).

Their performance is directly proportional to the energy consumption and the bill’s costs increase as it increases the presence of pollutants settle over time. On their surfaces we can see a gradual biological proliferation, which is the development of micro-organisms in risk of diffusion inside the environment. Finally, this type of filters involves frequent replacement and disposal costs (in fact there are toxic dangerous wastes, which have to be disposed as hazardous waste). In conclusion, the new mechanical’s filters generation (classes G, E and F) have very good performance during the initial stage of filtration, and then decrease considerably as the filter reaches the maximum concentration of particulate. Therefore they need to be replaced with new filters that initially ensure a good efficiency filtration.

RETROFIT FOR THE COMFORT AND ENERGETIC PERFORMANCE IMPROVEMENT

Plants characteristics with Electrostatic precipitators (electrostatic filters):

These are the basic features, to which is added an extremely important plus: an efficient antifungal and antibacterial action, in order to avoid the proliferation of bacteria colonies and molds in certain favourable conditions of temperature and humidity, often encountered in typical treatment plants air. For these reasons, and in order to reduce environmental impact, Expansion Electronic has implemented a retrofit’s action that allows you to replace the normal mechanical filters with those of new electrostatic generation one.

The advantages are mainly two:

MECHANICAL FILTER WITH ELECTROSTATIC CHARGE

In the electrostatic filtering systems technology there is an electrostatic effect when a polluting particle (dust, smoke, fibers, etc ...) has, on its surface an electric charges (positive and/or negative) that makes it adhere to another surface (filter’s fiber, walls, curtains, TV and laptop screens, etc..) with equal but opposite charge. If the particle mass is sufficiently small, the electric charge presents on its surface makes it adhere to another opposite electric charge, present on the surface of the mattress filter.

When this phenomenon is enhanced artificially, electrostatically charging the fibers of a filter you will obtained a “passive electrostatic filter”, which in order to work well must be made with very high electrical resistivity fibers, as for example the rectangular plastic fibers. Its negative aspect is that just the deposit of polluting particles on the filter fibers makes it immediately decrease the ability of pollution’s abatement.

Moreover, if the environment is particularly damp, the water contained in the air condenses on the surface of the fibers and eliminates them in a very short time each electric charge, transforming the product into a simple mechanical sieve filter. To overcome this problem the so-called ‘buffer’ filtering systems were created, in which the filtering means are submerged in an electric field which maintains the attraction power and the pollutants retention. The negative side is in the operation, starting from the fact that it depends on a filter mattress (the so-called buffer) that, even if electrostatically charged, presents the same disadvantages of the mechanical filters.

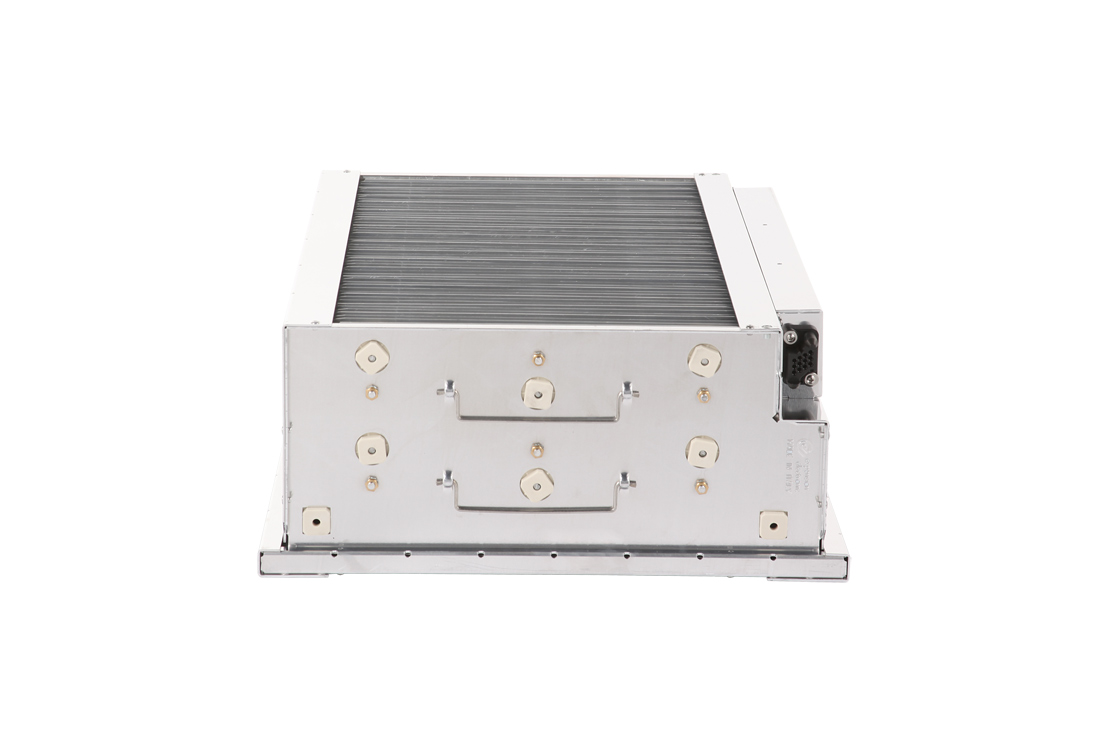

ELECTROSTATIC FILTER WITH ACTIVE PLATES

The active electrostatic filter utilizes aluminum active plates that are electrostatically charged to remove pollutants from the air. It employs a purification system that separates both solid (dust) and gaseous (oil vapors) contaminants from the incoming airflow. By generating a potential difference between the emission electrodes and the collection electrodes, the system separates pollutants from the gas flowing through the electrodes. This process electrically charges airborne particles, regardless of their size, due to the electric field generated by the emission electrodes. This field ionizes the particles, and as they pass through the collection field, the ions collide with the pollutants. The pollutants receive a portion of the ions' electric charge, causing them to precipitate and be captured and held by the collection plates. The end result is air that is completely free of pollutants of any type or size.